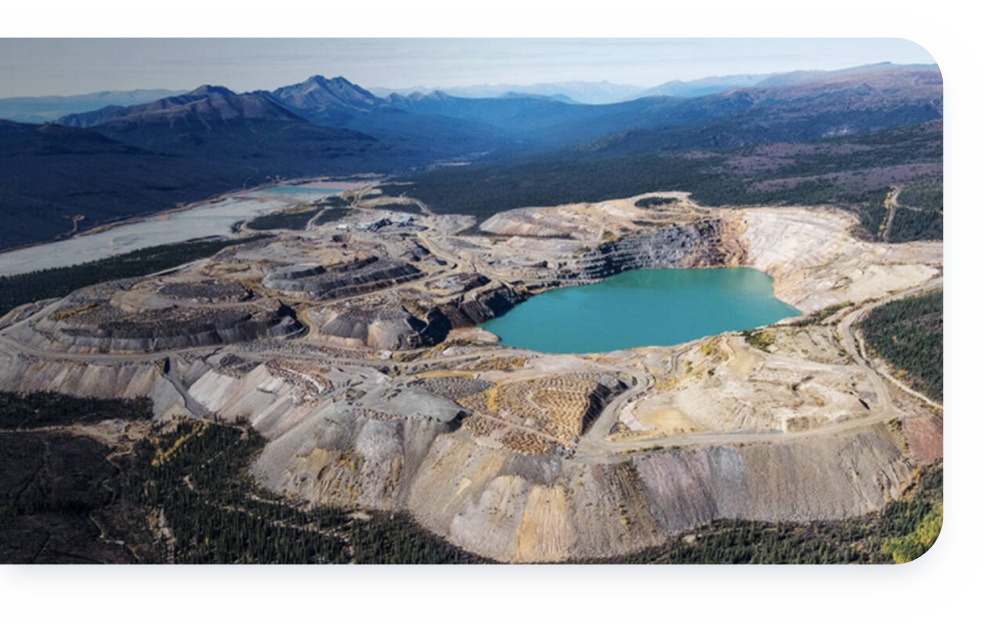

Faro Mine

Yukon, Canada

Problem: Even after mining at Faro Mine has stopped, acid mine drainage continues to produce massive volumes of highly acidic water contaminated with toxic levels of zinc and lead. Treating this water with lime is extremely costly, generates large volumes of lime-metal sludge for disposal, and requires hazardous acids to neutralize the treated water.

Solution: waterStrider’s technologies provide a simple, safe, and cost-effective solution to remove contaminants and neutralize pH in lime-treated water. waterStrider eliminated 99.9% of dissolved zinc and 99.9% of dissolved lead, producing only a small volume of stable, non-leachable solids.

After metal removal, Misty CO2™ safely neutralizes the pH of the water, eliminating the need for hazardous acids.